How to pass DOT inspection with faulty trailer ABS

Because of the global supply chain clusterfuck many essential truck and trailer parts have a wait list of several months. Everybody in the business heard of Freightliner CPC4 modules gone extinct, turning thousands of units into 10-ton paperweights. Recently I had a semi-trailer, that needed new TABS and the wait time was 6-8 weeks. So I came up with a temporary solution.

When a DOT inspector examines a semi-trailer, he looks for two clues that something is wrong:

1. The ABS light on the trailer doesn't turn on with ignition on for 2 seconds (indicating that the system initiated and passed all the tests).

2. The ABS light stays on after initializing, indicating there's a problem with the ABS.

This doesn't allow the driver to simply disconnect the light. Because even if you claim to the inspector, that it's simply a faulty light, he can still check the light on the dashboard of your truck, that also lights up for 2 seconds with ignition and turns off if no problem is detected. So we need to make sure both lights go through initialization properly.

Now the tractor dash light is an easy fix. All you need to do is cross the blue wire from the tractor to the red wire on the trailer. The electric cable connecting to the TABS has 4 wires:

1. Blue (AUX) - main power supply to the TABS, always on with ignition "On".

2. Red (Stop) - auxiliary power supply, only "on" when brakes are applied.

3. White/green - ABS light power.

4. White - ground.

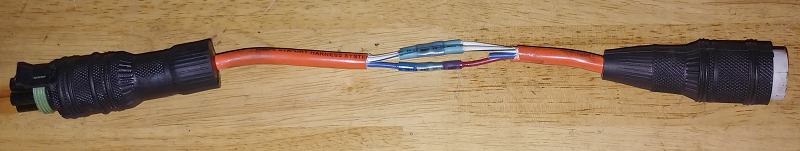

The idea is simple: TABS doesn't care if the power comes through the blue or red wire, but it uses the blue wire to send a modulated signal back to the tractor ECU in case of malfunction. If we cross blue wire from the tractor to red wire to the trailer (leaving the other ends hanging), TABS still receives power, but the malfunction signal doesn't reach tractor ECU (and the trailer ABS light on the dash doesn't stay "On"). If you have an extra cable laying around you can make an adapter, this way when you get new TABS, you simply unplug it without having to rewire everything back to normal.

Figure 1. TABS adapter

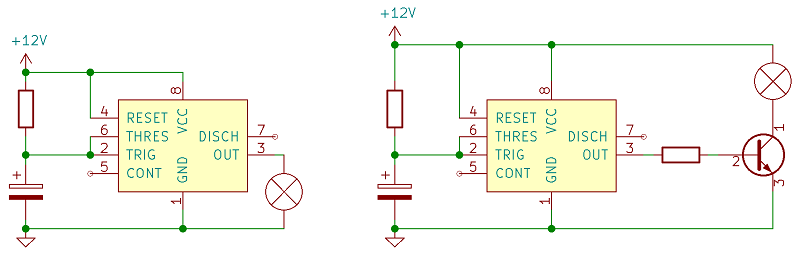

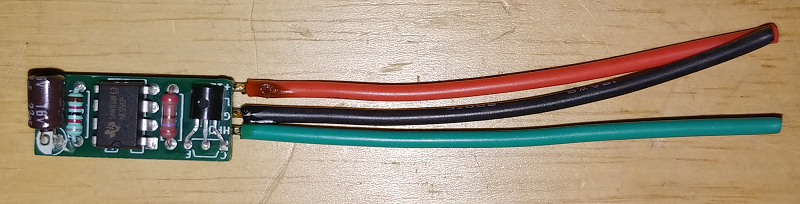

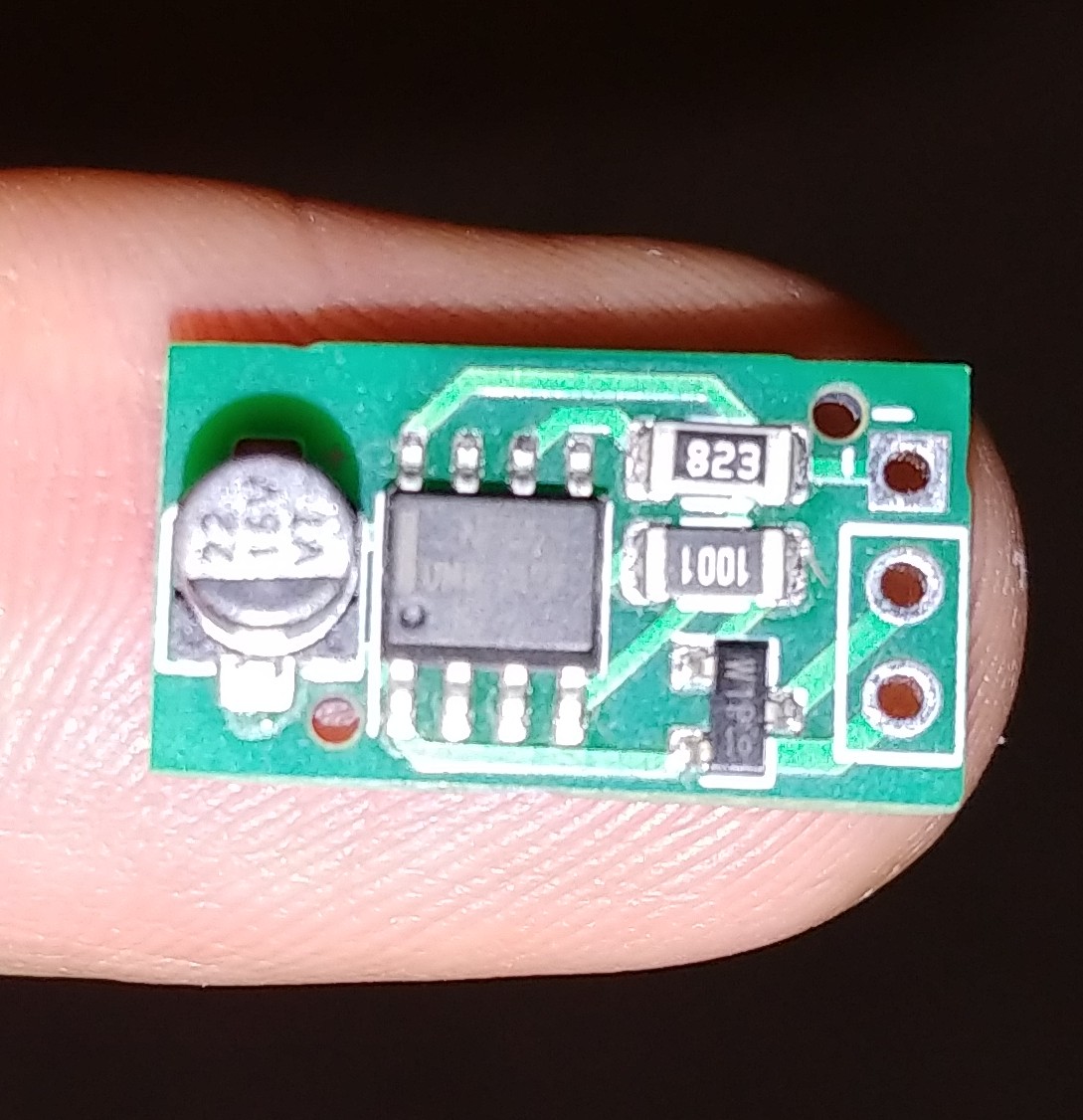

The second problem is a little more complicated and requires some basic electronics skills. We need to make a circuit board that turns the light on when power is applied and turns it off after two seconds. This is easily achievable with a NE555 timer. The IC can output 200 mA, which is enough to power a light up to 2.5W. And we can always add an extra transistor to raise it even higher.

Figure 2. Two ways to connect the lamp

Figure 3. Light simulator finished PCB

Figure 4. Light simulator finished PCB (SMT version)

By implementing both of this fixes we make it virtually impossible for a DOT inspector to suspect an ABS malfunction. Of course, there's also a chuff test, but even if they understood what it is, they would never go checking it if the ABS light isn't on.

Instructions and BOMs:

Attachments:

THT PCB Gerber (14 kB)

SMT PCB Gerber (12.7 kB)

Log in to leave comments